FAQ: what's the purpose of a release liner?

Posted on Tue, Aug 28, 2018

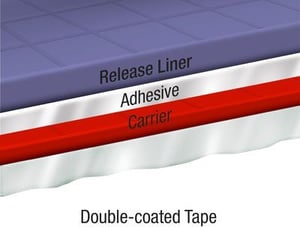

The release liner’s purpose is to provide a means to protect and transport an adhesive to its application point and prevent adhesives from sticking until the user is ready for application.

Typically, there are two formats = One side coated (C1S) or two side coated (C2S)

One side coated (C1S) release liners:

- C1S liners provide protection for an adhesive that is laminated to a film or paper substrate. In addition, because they provide a good, flat, uniform surface, they are used as a die-cutting base. These C1S liners primarily serve as a delivery mechanism for adhesives undergoing automatic or manual labeling and graphic arts applications.

Two side coated (C2S) release liners:

- C2S's also called differential release liner, is a paper or filmic web coated on both sides with silicon-based release coatings that are designed to provide differing release values to the specific adhesives applied to them.

Differential release liners provide a means to protect and transport a pressure-sensitive adhesive (PSA), fiber composite material or heat-sealable adhesive to its application point, where the liner can be removed to leave only the adhesive in place.

C2S release liner can carry two adhesives with a substrate in between that can be wound onto and unwound from a roll. This format is used when working with transfer adhesives, or using two different adhesives on two sides of a substrate. In either situation, the liner must have two different release values (surface energies) for proper performance to remove an adhesive product from a release liner surface.

Learn more in our Guide to Release Liners