"Thin Is In" - New Adhesives for Electronic Device assembly from 3M

Posted on Fri, Aug 15, 2014

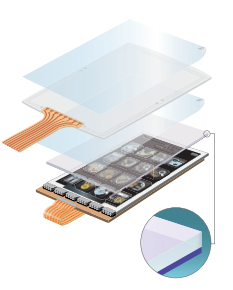

"Thin" is in these days, particularly when it comes to adhesives. 3M scientists recently rolled out a new line of ultra-thin adhesives. That’s the kind of thin that makes paper-thin seem downright portly.

These ultra-thin tapes are constructed using a high-tack standard acrylic spread over a thin polyester film. This makes the tape dimensionally stable and easy to die cut, laminate or slit for your application.

While this tape may be built like it's lightweight, it still has high initial adhesion on many types of surfaces. It’s also no slacker when it comes to shear holding power.

Exposures: 3M ultra-thin tapes can withstand

- humid conditions

- sun

- immersion in water

- extreme temperature shifts

- exposure to chemicals including oils, mild acids and alkalis

Think an ultra-thin adhesive tape might be a good option for your electronic device?

Call Gleicher Manufacturing Corp. to speak with one of our experts about the product. Gleicher experts have decades of experience working on electronics devices. They can help you find the ideal product to meet your device needs, and help you stay abreast of the multitude of new technologies and options coming on the market each year.

You’ve got to ask the right questions to get the right solution for your device.

With this in mind Gleicher recently created a free guide that outlines the items you should focus on when working with a converter and should be considered during the R&D process.

Starting a relationship with the converter early in the process can not only ensure that you get the right product to withstand environmental conditions such as heat or drop stress, but also that you lay the groundwork for a smooth production process, one that is efficient and minimizes waste.

Call Gleicher today to find out if the ultra-thin tapes can benefit your design so you can get production ready samples in hand for laboratory testing.