Consider Stress & Environment Factors When Choosing 3M Adhesives

Posted on Mon, Mar 05, 2012

When identifying the right adhesive to improve your products look and functionality you need to consider the environment and stress factors that the bond will be subjected to.

Ask yourself if your device/product is subject to these environmental factors:

• Inside/outside end use

• UV exposure

• Chemical exposure

• Moisture

• Temperature ranges

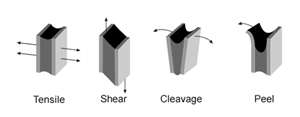

In addition evaluate the type of stress your device/product will undergo. the 4 common types of stress are identified and explained below.

• Tensile: is pull exerted equally over the entire joint. Pull direction is straight and away from the adhesive bond

• Shear: is pull directed across the adhesive, forcing the substrates to slide over each other

• Cleavage: is pull concentrated at one edge of the joint, exerting a prying force on the bond. The other edge of the joint is theoretically under zero stress

• Peel: is concentrated along a thin line at the edge of the bond where one substrate is flexible. The line is the exact point where an adhesive would separate if the flexible surface were peeled away from its mating surface. Once peeling has begun, the stress line stays out in front of the advancing bond separation.

These factors play a key role in simplifying your adhesive decisions. Most adhesive tapes perform better when the primary stress if tensile or shear. In most industrial applications, however, a combination of stresses are involved that may include cleavage and peel.

In general epoxy adhesives hold up best to harsh environments.

Understanding surface conditions is the first step to determining how much bonding strength will be needed and which adhesives work best. After identifying surface conditions and environmental factors your choices should feel narrower. To learn more about which 3M adhesive will benefit your device best talk to a gleicher representative