Choosing 3M Thermal Heat Shield Tapes for LED Assembly or Heat Sink Mounting

Posted on Sun, Nov 01, 2015

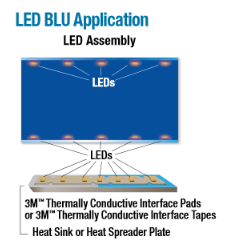

Summary: Today’s high intensity LEDs are opening up new opportunities for cost savings and reduced power consumption. However, they also generate more heat than conventional LEDs. 3M™ Thermal Interface Materials provide efficient thermal transfer for long-term reliability and performance optimization in applications using high brightness LEDs.

Summary: Today’s high intensity LEDs are opening up new opportunities for cost savings and reduced power consumption. However, they also generate more heat than conventional LEDs. 3M™ Thermal Interface Materials provide efficient thermal transfer for long-term reliability and performance optimization in applications using high brightness LEDs.

Continuous Operating Temperature versus Component Performance:

It’s important to remember that the higher the temperature at which LEDs operate, the less efficient they become – making improved thermal management essential for optimal performance. That’s where Gleicher can help naviagate the 3M options.

3M™ Thermal Interface Materials provide efficient thermal transfer for long-term reliability and performance optimization in applications using high brightness LEDs. Especially in external applications of LEDs, durability of the thermal interface is important to support efficiency in different environmental conditions. 3M Thermal Interface Materials have a proven track record of durability and high thermal performance in a variety of environmental conditions to meet the demanding needs of applications today and in the future.

Let there be light! A Display Case In A Museum

- Goal - to show off the contents of the case while being easy on the eyes, all the while not affecting the artifact inside.

- Solution – think outside the box. Using tape, epoxy, and reflective materials, we created a solution that fastened the high intensity LED lighting fixtures to the frame, evening distributing the light and the heat.

Some key questions: What’s the continuous operating temp? Is the assembly manual or automated? Once you know these answers you can begin to narrow the list of options.

Thermally Conductive Tape, Pads, or Epoxy Adhesives - which one is right for your application?

Designed to be the heat-transfer path between heat-generating components and heat sinks or other cooling devices (e.g., fans, heat spreaders or heat pipes), these materials are available with a variety of characteristics.

Thermal Heat Sink Tapes:

This range of high adhesion thin thermal tapes offers bonding strength, shock absorption, and efficient heat dissipation for applications such as heat sink mounting and LED lighting thermal management.

These tapes provide excellent long term reliability, electrical insulation and flame retardant performance. 3M thermal transfer tapes are available in a variety of thicknesses to meet your most challenging thermal applications.

Applications: Heatsink-Thermal Interface Attachment, Battery Thermal Management, LED Lighting Thermal Management, Heatsink-Thermal Interface-Non Bonding, Flex Bonding, Thermal Interface-Damping-Cushioning

Thermal Pads:

Available in silicone and acrylic formulations, 3M thermal transfer pads are soft and conformable to provide maximum wet out for effective heat transfer and vibration damping for your most demanding thermal applications such as LED and consumer electronic device assembly. 3M acrylic thermal gap pads have a unique surface tack that enables pre-positioning in multi-layer lamination applications. Both silicone and acrylic thermal gap fillers provide excellent handling capabilities and can be die cut to fit most applications. Applications:

Applications: Battery Thermal Management, Thermal Gap Pad, LED Lighting Thermal Management, Thermal Interface-Damping-Cushioning

Thermally Conductive Epoxy:

These epoxies and urethanes are ideal for applications requiring high adhesive strength and excellent surface wet-out. They can provide a thermal interface between IC packages or PCBs and heat sinks or other cooling devices as well be used as thermally conductive potting compounds.

Applications: Thermal Material Potting, Heatsink-Thermal Interface Attachment, Battery Thermal Management, LED Lighting Thermal Management, Heatsink-Thermal Interface-Non Bonding

A Combination Solution:

The fork in the road is the continuous operating temperature of your application. As in the case study above, the team at Gleicher can work with you to manage heat, adjust reflection, and find multiple ways to fasten the LED’s. And there are other variables to consider adhesive strength, thickness and gap filling, repositioning, and of course all the exposures.

How can Gleicher help? Talk to Engineering - Request Custom Samples - Get a Quote